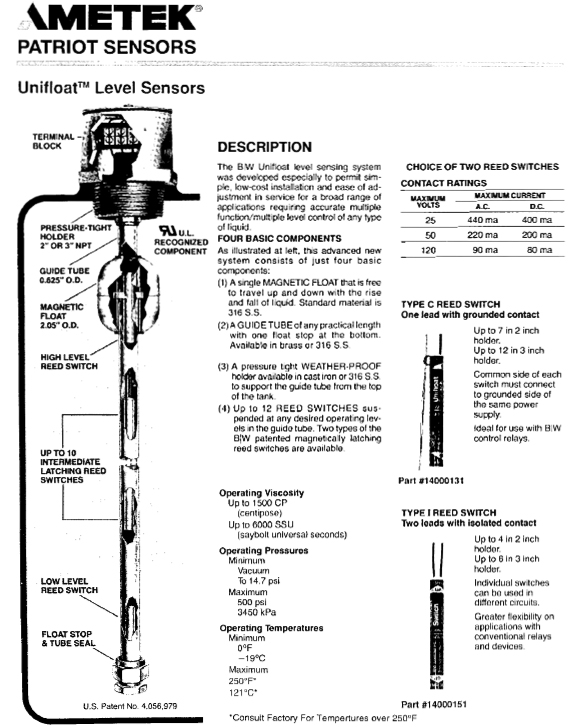

For B/W float sensors , the 7014 Series Unifloat sensor uses a magnetized free-moving float on a guide tube. Inside the guide tube are positioned B/W patented magnetic latching reed switches. As the float passes the switch, the magnetic field opens or closes the switch, which then makes or breaks the sensing circuit. For a pump-down example, a normally open (N.O.) switch at high level would close at the actuation point, completing the sensing circuit and starting the pump. Because of the unique latching feature, the switch remains closed until the float passes below it on falling level. As the float passes back through the switch, it returns to N.O. position. See application notes /specs for the Unifloat.

For continuous level monitoring, the Pro-Stik employs B/W's patented magnetostrictive technology. A movable float with an embedded magnet is placed on a guide tube. Inside the tube is a magnetostrictive wire. Level measurement is retrieved by sending a current pulse down the wire. The interaction of the current pulse and the magnetic field produces a torsional strain pulse on the wire.The strain pulse travels up the wire at a known speed and interacts with a pickup device to provide an electronic pulse. The time interval between this pulse and the initial primary current pulse is converted into a 4-20 mA signal which represents the position of the float.

Other accessories may be needed, such as wire connectors for wire suspension electrodes, rod connectors and spacers, enclosures, etc.

How B/W Controls Work

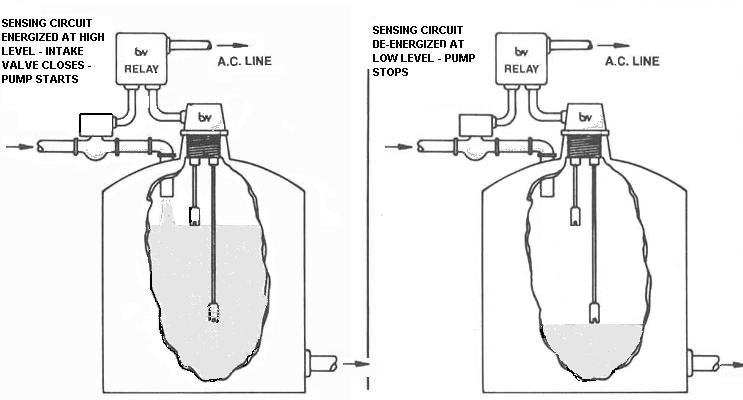

In a typical pump down application, as the liquid rises in the tank and touches the upper electrode (pump-start), the sensing circuit is completed, and the relay contacts close (energize) and the pump starts. When the liquid falls below the lower electrode (pump-stop) the circuit is broken and the pump shuts off. This proven approach is simple, low-cost and reliable. For a more detailed Principle of Operation see page 2 applications/specs for the 1500 Series Induction Relay

A typical B/W liquid level control system uses the electrical conductivity of the liquid to cycle the pump, or any other power driven device related to the level of the liquid. As the liquid rises and falls, it contacts the sensor suspended in the tank, making or breaking the sensing circuit. The sensing circuit is very low energy and varies in voltage.

- Control relay (controller)

- Type of level sensor

- Type of electrode holder

To Place Your Order Call 704-366-0031

Fast Shipping

Factory Direct Pricing

TO PLACE YOUR ORDER CALL (704) 366-0031

Engineered Equipment And Controls

Our friendly , knowledgeable sales staff is ready to assist you with your liquid management needs.

Factory Direct Pricing, Fast Shipping, Big Inventory!

To Place Your Order Call 704-366-0031

10700 Sikes Pl. - Charlotte, NC 28277 - Fax 704-366-0091

Ametek Drexelbrook Sensors and Controls

- B.W Allen Co.

B.W. Allen Company

~ Liquid Level Controls and Water Monitoring Solutions since 1961 ~